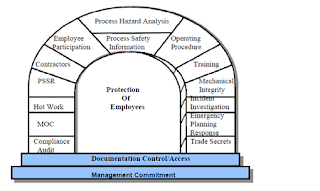

Process

safety management or (PSM) is an analytical tool centered on preventing

releases of any substance defined as a highly hazardous chemical. PSM refers to a set of approaches that are used to

manage hazards associated with the industrial processes and it is intended to

reduce the frequency and severity of incidents resulting from releases of

chemicals and other energy sources (US OSHA 1993). These standards are composed

of organizational and operational procedures, design guidance, audit programs,

and convey of other methods. Here I have included the 14 step process and

an explanation from OSHA’s website.

1) Develop and maintain written safety information identifying workplace

chemical and process hazards, equipment used in the processes, and technology

used in the processes.

(2) Perform a workplace hazard assessment,

including, as appropriate, identification of potential sources of accidental

releases, identification of any previous release within the facility that had a

potential for catastrophic consequences in the workplace, estimation of

workplace effects of a range of releases, and estimation of the health and

safety effects of such a range on employees.

(3) Consult with employees and their

representatives on the development and conduct of hazard assessments and the

development of chemical accident prevention plans and provide access to these

and other records required under the standard.

(4) Establish a system to respond to

the workplace hazard assessment findings, which shall address prevention, mitigation,

and emergency responses.

(5) Review periodically the workplace hazard assessment

and response system.

(6) Develop and implement written

operating procedures for the chemical processes, including procedures for each

operating phase, operating limitations, and safety and health considerations.

(7) Provide written safety and

operating information for employees and employee training in operating

procedures, by emphasizing hazards and safe practices that must be developed

and made available.

(8) Ensure contractors and contract

employees are provided with appropriate information and training;

(9) Train and educate employees and

contractors in emergency response procedures in a manner as comprehensive and

effective as that required by the regulation promulgated pursuant to section

126(d) of the Superfund Amendments and Reauthorization Act.

(10) Establish a quality assurance

program to ensure that initial process-related equipment, maintenance

materials, and spare parts are fabricated and installed consistent with design

specifications; Process Safety Management 4.

(11) Establish maintenance systems for

critical process-related equipment, including written procedures, employee

training, appropriate inspections, and testing of such equipment to ensure ongoing

mechanical integrity.

(12) Conduct pre-startup safety reviews

of all newly installed or modified equipment.

(13) Establish and implement written

procedures managing change to process chemicals, technology, equipment and

facilities.

(14) Investigate every incident that results

in or could have resulted in a major accident in the workplace, with any

findings to be reviewed by operating personnel and modifications made, if

appropriate.

Process Safety has developed over

the years. Unfortunately, this is often

due to severe incidents. But it is

through these incidents that we learn.

OSHA and the EPA have a huge influence on the PSM. OSHA, covering the safety of the employees. And the EPA covering the environmental risks

that industry causes. However the two

can be heavily tied, for example the Bhopal, India release was an environmental

pollutant that cause a lot of harm to people (not necessarily employees in this

case). This is just one example of how the

two are heavily intertwined.